Core Capabilities

- Engineering & Design: Complete mechanical, electrical, and software engineering support, including prototyping and UL certification.

- Manufacturing & Assembly: Flexible lean production lines capable of building low- to mid-volume complex equipment, with full quality assurance and testing.

- Installation & Project Management: Turnkey installations across hospitals, universities, casinos, and industrial facilities, with project planning, logistics, and on-site execution.

- Service & Support: Dedicated service team providing maintenance, warranty support, and parts management through a cradle-to-grave lifecycle approach.

- Supply Chain Strength: Established relationships with local and international suppliers for sheet metal, machining, and electronics, enabling cost efficiency and speed to market.

Why Cortex

Cradle-to-Grave Capabilities:

- Engineering, design, assembly, installation, service, and parts, all managed in-house.

- Multiple proven third-party metalworking partners promote competition for faster turnaround, tighter quality control, and stronger accountability.

- Hands-off experience: Customers don’t need to provide constant direction; we excel at taking concepts and executing them to completion.

Flexible, Scalable, and Fast:

- Lean, responsive organization that can pivot quickly.

- Fast-track prototyping, pilot builds, and change management.

- Ability to scale from pilot to full production with speed.

- Dedicated facility with 57,000 sq. ft. of manufacturing and warehouse space.

Cost-Saving Innovation:

- Proven ability to reduce total cost through component changes, design improvements, and process efficiencies without sacrificing quality or compliance.

Proximity & Responsiveness:

- Centrally located in Cincinnati, OH within 1-day transit to most U.S. sites.

- On-site installation and service teams reduce downtime and field risk.

- Quality-focused with documented QC process including ATP, FAT, and CAPA for continuous improvement.

- Customer-centric: Dedicated account management and transparent communication, with tools like NetSuite, Salesforce, and MaintainX to streamline reporting and responsiveness.

Our Logo

- Innovation is at the Center of All We Do

- Colors - Blend of CTG

- Four Corners & Four Core Values

- Four Prongs Supporting Each Value

- Mark Resembles Outside of the Box Thinking

- Lowercase is Humble

- Uppercase is Confident

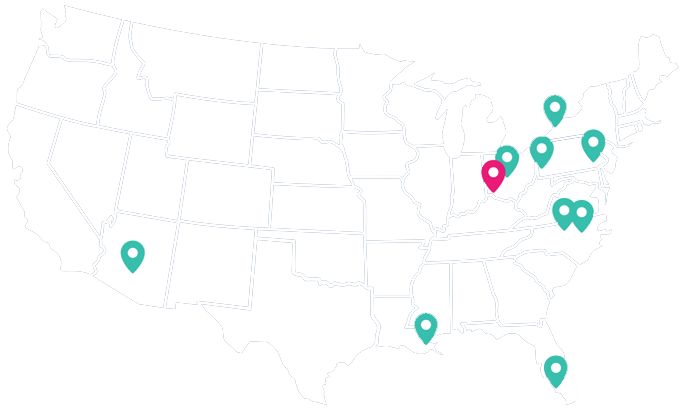

National Coverage

- Arizona

- Florida

- Louisiana

- New York

- North Carolina

- Ohio (headquarters)

- Pennsylvania

Experience & Customers

- Trusted partner of a Fortune 500 Company for 10 years, supporting a fleet of over 4,600 machines across North America. This relationship has given us deep familiarity with the requirements of the healthcare and other regulated industries.

- Successfully managed more than 1,200 national installation projects in the past 8 years, coordinating travel, labor, and logistics across multiple states.

- Over 2,000 garment dispensing/ return machines manufactured to date.

- Customers benefit from exceptional reliability, with warranty claims consistently well below industry averages. Cortex maintains a low warranty claim rate, minimizing downtime and disruption.

- Proven independence and ownership: Customers often bring Cortex general challenges or ambiguous requests, and we take full responsibility to carry them through to completion with minimal oversight.

Strategic Positioning

While Cortex’s history has been focused on a single large-scale customer, this has proven to be a strength: we are a dedicated partner, not just a vendor. Our track record demonstrates the value of a focused, long-term partnership, and positions us uniquely as a reliable “anchor builder” for organizations seeking a U.S.-based design, manufacturing and service partner.

Our Team

- 45 Cortex employees across engineering, manufacturing, service, installation, purchasing, and accounting with support from 145 CTG employees.

- Highly trained technicians with an average of 15 years’ experience in installing and maintaining electromechanical systems.

- Leadership team with deep backgrounds in operations, engineering, and customer service, ensuring both technical execution and responsive support.

Our People

Core Values

What would Jerry Horan do?

Embrace agility, demonstrate professionalism, and fuel actions with positivity and strategic foresight.

Invest in people

Provide growth tools, balance life's aspects, celebrate achievements, and foster relationships deeply.

Kickn' ass everyday

Reject complacency, approach with readiness, uphold high standards, and install confidence and trust.

Don't forget how we got here

Maintain humility, adopt a can-do attitude, amplify impact, and attract talent through dedicated excellence.

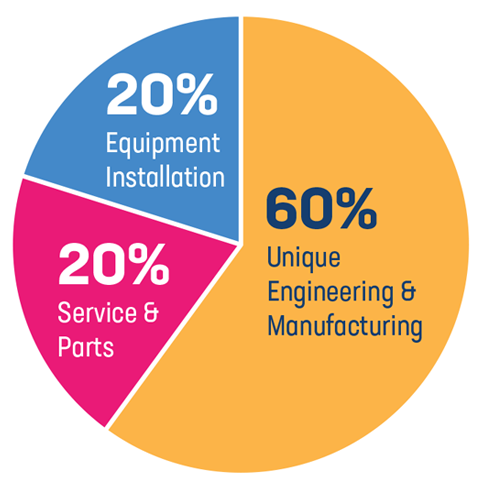

Revenue Analysis

About Us

Cortex Engineered Solutions is an employee focused and innovation engineering driven organization. As one of four divisions of Cleaning Technologies Group, we strive to bring unique mechanical and electrical solutions to our customer.

Through the utilization of lean manufacturing and 5S principles we ensure that our pricing is competitive, and our quality is consistent on all our product offerings. With a concerted focus on local service presence, our geographic footprint continues to expand across the United States.

We live by our Core Values every day, always keeping our corporate Vision at the forefront of everything that we do- Be Our Customer’s First Choice.